Endur Insulating Glass

A lot of manufacturers talk about performance, i.e., U-Factors and SHGCs. But what about durability? Performance over the long haul?

That’s where Endur IG™ excels. Endur IG continues the Cardinal tradition of long-term performance. It delivers the industry’s lowest failure rate, the only comprehensive 20-year factory warranty plus outstanding thermal performance and solar control.

Exceptional longevity and performance … that’s how we help protect your brand and your reputation. New Endur IG, what the future of insulating glass looks like.

With over 500,000,000 IG units under warranty, Cardinal knows a thing or two about building long-lasting IG units. Our units have proven themselves over and over in the field and in the lab. The only way we’d change a thing is if we could improve it. We have.

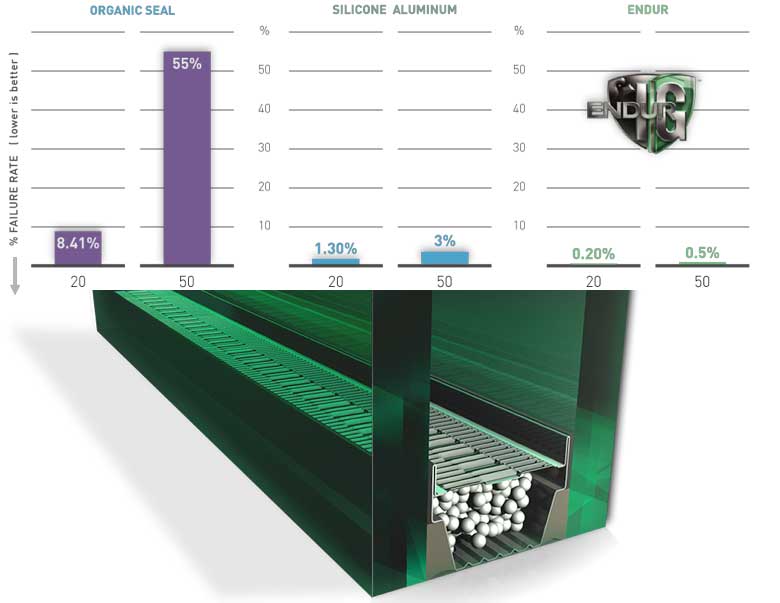

The industry’s lowest failure rate.

Endur IG is built on the proven technologies that help Cardinal IG units achieve the industry’s lowest failure rate – only 0.2% over twenty years – allowing us to offer the industry’s only comprehensive 20-year factory warranty, because endurance is just as important as performance.

CARDINAL IG SEAL DURABILITY

A comparison of our warranty and long-term projections.

20 years: actual data || 50 years: projected || lower is better.

A new warm-edge, stainless steel spacer is key.

Upgrading our proven XL Edge® spacer is an entirely new warmer edge stainless steel spacer, improving sightline temperature by 1-2 degrees and improving resistance to condensation. The corrugated shape adds strength. Bent corners – not notched or open joints – create a continuous impermeable metal barrier around the entire perimeter, keeping moisture out and argon in. Overlapping seams along ears allow breathing. The new spacer is also more aesthetically pleasing. Finally, our Endur IG unit can improve overall window U-Factor up to 0.005 – a big deal when chasing the last 0.01 decimal for compliance to energy code.

Can you afford failure?

Excessive IG unit failure rates can severely affect your profit margins. Reduce your risk with Endur IG, where early failure is not an option. Reducing failure rates reduces your warranty service costs as well.

Assuming a $500 service call to reglaze a failed IG unit under warranty, and with an 8% seal failure rate, the window manufacturer would need to add $40 to the cost of the window to cover warranty costs.

With a 0.20% seal failure rate such as Cardinal’s, the window manufacturer would need to add just $0.50 to the window price to cover warranty claims.

Endur IG excels in rigorous P-1 test.

Cardinal also subjects IG units to the more demanding P-1 test (an industry-accepted test) to determine long-term seal durability. Test criteria simulate worst-case, real-world scenarios: 140º F, constant UV exposure and 100% humidity.

Results showed that competitive seal systems failed within 8 to 22 weeks of testing. Endur IG, utilizing silicone dual-seal construction, routinely passes 80 weeks exposure with dew points below 0°F (-18°C).

Endur’s energy efficiency

Select the LoĒ® glass that optimizes your home’s performance, and know that Endur IG will stand up to the extremes of your weather. Through the hottest summers and coldest winters, Endur IG is engineered for maximum seal durability. With its proven durability Endur IG will save heating and cooling energy for years to come.

SIGHTLINE TEMPERATURE

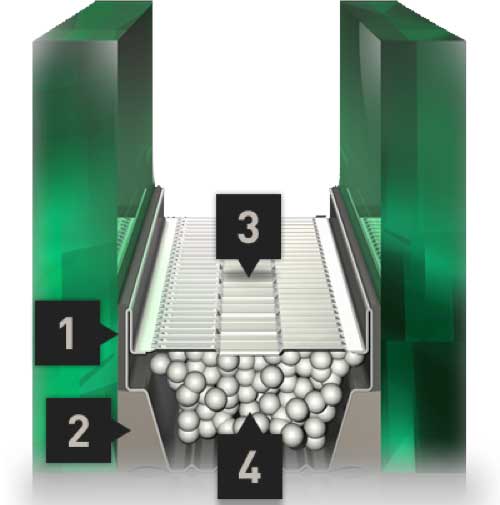

What’s inside a Cardinal IG unit?

Cardinal IG units consist of two or three lites of glass separated by an inorganic metal spacer.

- Primary Seal: Polyisobutylene (PIB) minimizes moisture permeation, is UV resistant and provides an outstanding argon barrier.

- Secondary Seal: Specially formulated silicone for IG units provides long-term adhesion, is unaffected by UV exposure and provides excellent durability when exposed to moisture. Silicone also provides structural integrity.

- Spacer: Stainless steel spacer features a roll form design to provide maximum area for primary and secondary sealant coverage. It provides increased resistance to condensation and less stress on IG seal system. No polymer content eliminates the risk of chemical fogging.

- Desiccants: Beaded molecular sieve provides initial frost points below -65°F. Desiccant assures optimum moisture adsorption while minimizing the effects of temperature-related pressure changes.

ENERGY STAR compliance.

Cardinal’s comprehensive portfolio of glass products can help you meet the 2015 ENERGY STAR guidelines using double-pane glass across the entire country. Start with LoĒ3-366 for SHGC compliance in the south and add LoĒ-i89 to meet northern U-Factors. Top it off with Endur IG, and you’ve got long-term durability to match your customers’ energy efficiency goals.

Limitless coating choices.

For ultimate performance glass, LoĒ³-366 delivers the perfect balance of solar control and high visibility, while our LoĒ³-340 controls glare and blocks oppressive solar heat gain.

If you need high solar gain glass to allow the winter sun’s heat to pass into the home while blocking heat loss, LoĒ-180 is the choice for you. Add in a layer of LoĒ-i89 to any glass unit to lower u-factors further and give an even warmer interior.

Protect your glass in transit and on the construction site with Preserve protective film. And keep your windows cleaner longer and easier with Neat naturally clean glass. For impact resistance and security, choose our Sea-Storm hurricane-resistant laminated glass.

THE FUTURE IS HERE

The future of insulating glass is here with Endur IG. With its unparalleled longevity and outstanding thermal performance, Endur IG stands in a class of its own. Be part of the Endur IG evolution.

*Technical data information provided by Cardinal Glass Industries.